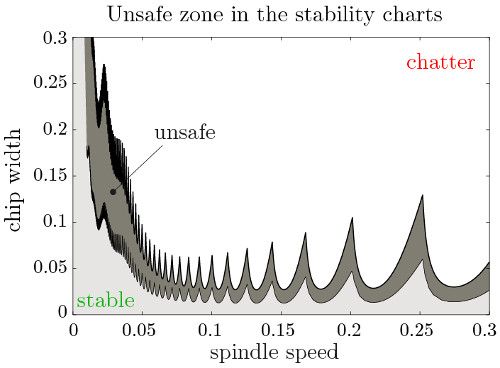

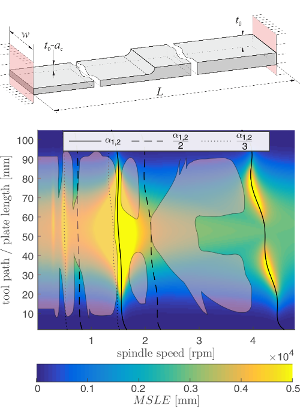

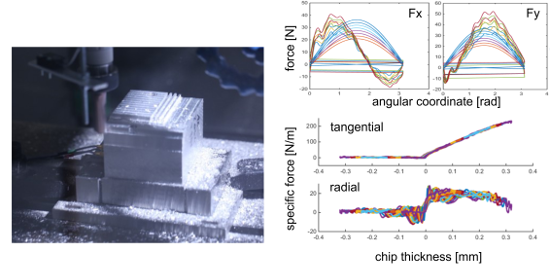

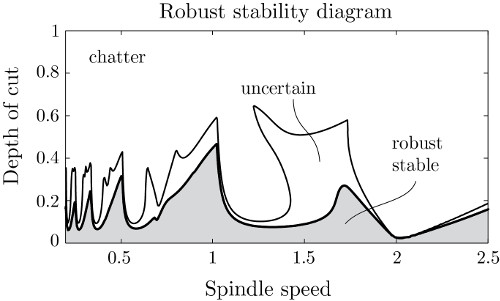

Experimental cutting tests often show different dynamic behavior from the one predicted by means of theoretical mechanical models. One reason behind this observation is the existence of nonlinearities in the machine tool-workpiece system. For instance, the cutting force is typically a nonlinear function of the chip thickness. Due to this nonlinearity, the stability lobe diagrams determined by standard linear stability analysis often fail to predict the region of chatter-free technological parameters. Namely, there exists an unsafe zone in the stability lobe diagrams of machining, where the cutting process is linearly stable, but machine tool chatter may still initiate for large enough disturbances like material inhomogeneity, holes in the workpiece material or external excitation. As a result of this research, we derived a simple analytical formula to estimate the unsafe parameter region. This way, the proper selection of the technological parameters used for machining becomes possible, which guarantees the avoidance of machine tool chatter caused by large disturbances.